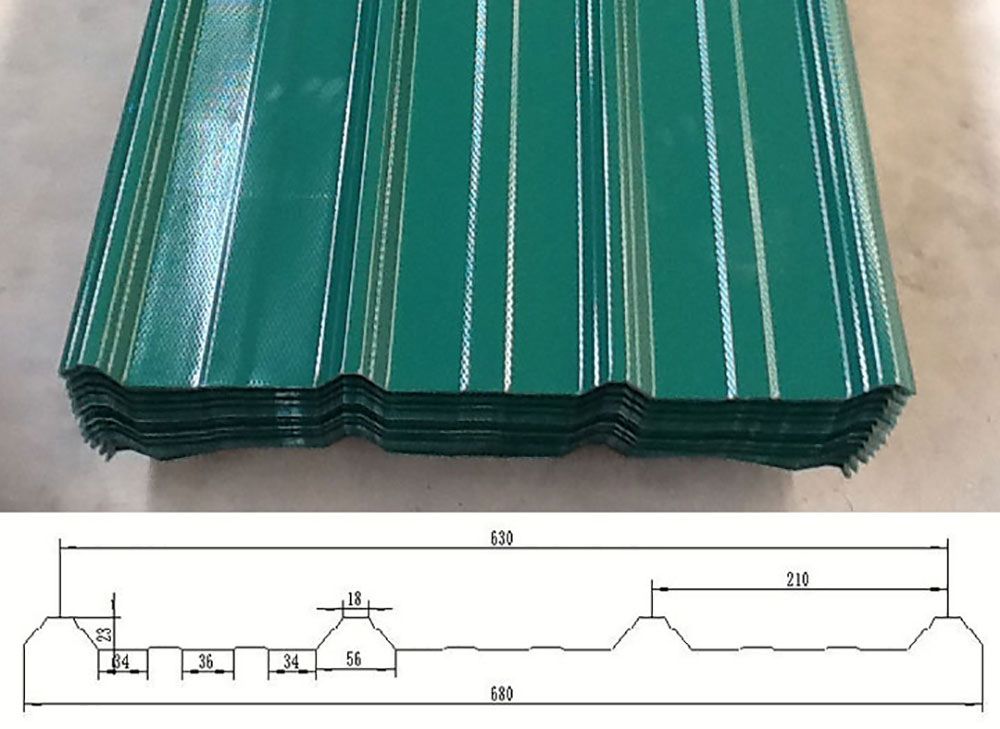

Trapezoidal sheets is a perfect combination of quality and aesthetics. Their universal profile allows you to create a robust roofing or a façade. A large selection of profiles and metal sheet varieties combined with cutting to size makes this product suitable for a very wide variety of applications.

The low-profile metal sheet (T3, T7, T8, T14) is applied for the construction of façades and roofs of houses, garages, small commercial buildings and suspended ceilings in industrial buildings. Slightly higher profiles (T14, T18, T18Eko) are used for roofs with larger spans, as well as for filling panels for industrial fences.

Higher profiles (T35 and T55), due to their durability, are used for the construction of large industrial facilities, production halls and load bearing structures.

Box profile metal sheet is a robust and economical material. It is available in a selection of coatings and colours, and meets the most diverse expectations.