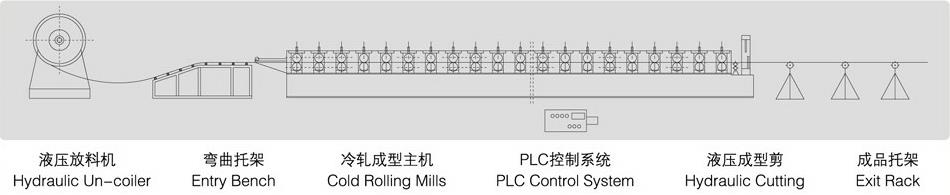

Machine Appearance

Main Components

1. Manual Decoiler

2. Feeding Platform

3. Automatic Pre-Cutting Device

4. Roll Forming Machine

5. Hydraulic Cutting Device

6. Hydraulic Curved Crimping Device

7. Pump Station

8. PLC Control System

9. Receiving Table

Technical Specification

Working Process

The complete roll forming machine line includes decoiler, forming machine, computer controlling system and run out tables. Our machines are equipped with a computer controlling system to keep prodcts accurate.

Machine Parameters

NO | Type | Specification | |

1 | Raw material | Type | PPGI/GI |

Material width | 1200 mm | ||

Thickness | 0.3-0.6 mm | ||

2 | Decoiler | Operation | Manual |

Weight apacity | 5 Tons | ||

3 | Roll Forming Machine | Roller station | 20 steps |

Diameter of shaft | 70 mm-0.01~0.03 | ||

Shaft Material | 45# with 0.05mm chrome | ||

Roller Material | 45# Forged Steel | ||

Transmission | Gear & Sprocket | ||

Bearing Type | 6210 | ||

Under Frame | H-beam | ||

Sidewall Frame | 18 mm Steel Plate | ||

Driving Type | Servo Motor 7.5KW | ||

Cutting Type | Guide Pillar with Electrical Motor 5.5KW | ||

Cutting Blade | Cr12Mov | ||

Voltage | 380V/50HZ, 3 phase | ||

Working speed | 20-25 m/min | ||

5 | Control box | Electric box | Import Brand PLC control system, inventer |

PLC brand | Delta/Siemens/Pansonic | ||

Inverter brand | Delta/Siemens/Sanjing | ||

Language | Chinese / English | ||

Production Parameters

Copyright © Cangzhou Forward Roll Forming Machinery Manufacturing Co.,Ltd All Rights Reserved Sitemap | Technical Support